We’ve all heard the adage, “It’s not the voltage that kills; it’s the current.” It is true, but there’s more to electrical safety than just this simple principle.

Workers who work with electricity are exposed to many hazards. These include arc flash and shock. These can result in serious injuries or death.

Table of Contents

Safety

Electricity and equipment can be dangerous, especially when workers must manually interact with machinery. Electrical controls help to eliminate some of the potential hazards by providing easy access to shut-off switches. They can even limit the amount of power being used for equipment.

They can also make your workplace more reliable by giving you real-time data on every change within the electric system and the authority to control it as needed. This can improve the consistency, repeatability and reliability of industrial processes, which results in higher product quality.

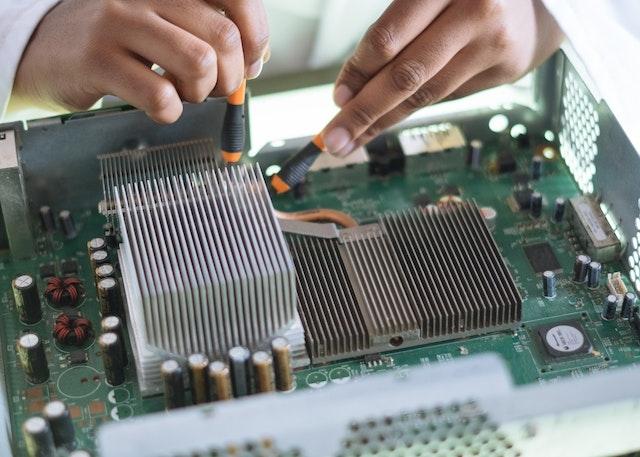

An electrical control panel consists of an enclosure and multiple components such as relays, switches, circuit breakers and fuses. The fuses and circuit breakers are designed to disconnect electricity from equipment when overloaded, which can otherwise cause fires or damage the wires and components. These devices are especially important for wet environments where water or chemicals may corrode insulation, creating a fire hazard.

Efficiency

Electrical equipment controls enable automated systems to perform at a higher level of precision, reducing waste and minimizing variations in output quality. This translates into lower energy costs for facilities that use such technologies.

Electrical power distribution system reliability is important to overall production plant operations, as downtime can lead to expensive revenue loss. Knowledge of the reliability history of specific pieces of equipment enables the design of cost-effective reliability mitigation strategies, such as transformers, service tap changers, harmonic mitigators, and power conditioning.

It is also critical to understand how power quality impacts the life expectancy of electrical equipment. This includes assessing equipment’s available fault current rating and power-quality conditions, including utility voltage regulation, surges, brownouts, and harmonics.

Reliability

Electrical equipment and machinery require defined functions and orderly control to achieve various process goals. Electrical control panels, like the breaker panel in your home or office, carry these out.

Working with electricity poses a significant risk to employees, especially when the equipment has been improperly used or maintained. This increased risk of injury can be due to shock/electrocution, arc flash or fire.

Employees must take several precautions to minimize the risks when using or handling electrical equipment. For example, they must wear insulated gloves and footwear. They must ensure that all power cords have sufficient insulation and are not contaminated with corrosive chemicals or solvents. Moreover, they must be plugged in correctly to avoid overloading the circuits. They should also check the fuses and circuit breakers to ensure they are not overloaded or damaged. In addition, they must inspect their workspace regularly for signs of damage or other safety hazards.

Maintenance

Electrical equipment and power systems require regular inspection, testing, and servicing to identify issues early. This prevents unexpected equipment deterioration, failure and hazardous conditions, such as fires. It also improves performance and extends the life of your devices.

Your facility staff and students should understand electrical safety hazards, including shock/electrocution, arc flash and fires. They should know the risks of mishandling and not performing maintenance on live electrical equipment and the importance of proper Lockout/Tagout procedures before any inspection or repair.

Your electric equipment manufacturer can provide a proper electrical maintenance program that should include a schedule for all inspections, tests and repairs. You should also have a record of these activities. It would help to keep spares on hand to speed up your maintenance process and minimize downtime. Additionally, you should ensure that any workspace or access to equipment is large enough for people to perform these tasks safely. You should also ensure that your equipment is not blocked by anything, such as furniture or rugs.

Also Read – Applying for SSDI with Long COVID: Tips and Advice